Research Activities: Anti-Reflective Coatings for the SPT-3G Instrument

The ObsCos lab is contributing to the next generation camera being built with collaborators from Fermi National Accelerator Laboratory, Argonne National Laboratory, the University of Chicago, UC Berkeley, and many other institutions. The work being done at University of Illinois is focused on developing cryogenic optics and anti-reflective coatings for millimeter-wavelength astronomy.

The ObsCos lab is contributing to the next generation camera being built with collaborators from Fermi National Accelerator Laboratory, Argonne National Laboratory, the University of Chicago, UC Berkeley, and many other institutions. The work being done at University of Illinois is focused on developing cryogenic optics and anti-reflective coatings for millimeter-wavelength astronomy.

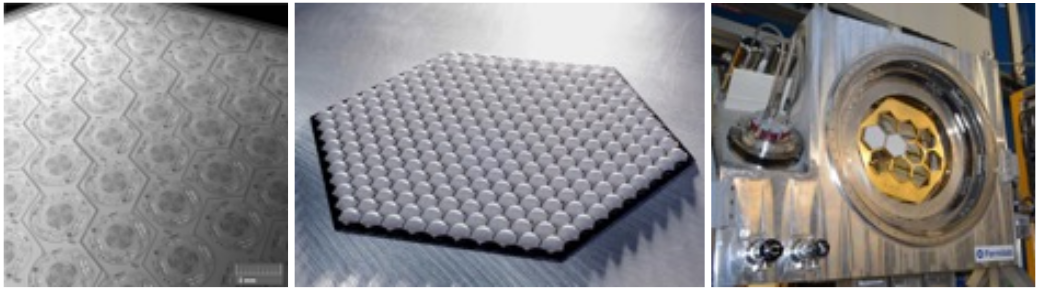

The ObsCos group at Illinois is responsible for fabricating arrays of lenslets for SPT-3G. These lenses couple radiation from the sky to the detectors. In addition, an anti-reflective coating is applied to the arrays, and laser cut between lenslets to avoid stress due to thermal contraction when cooled to 300 mK.

Research Activities: Next-Generation Anti-Reflective Coatings

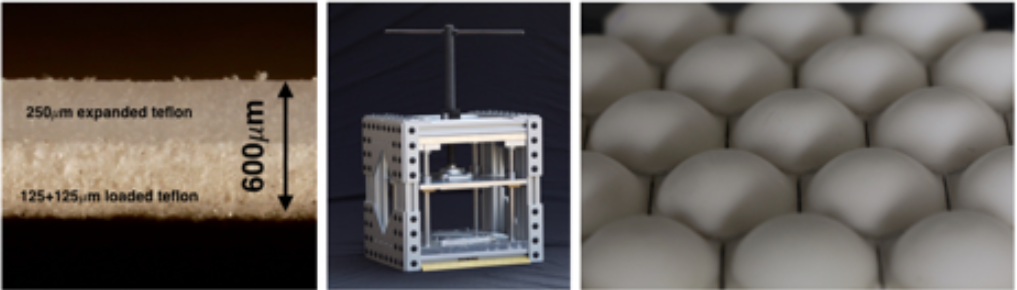

In addition to the work being done for the SPT-3G third generation camera, the ObsCos lab is working on the larger problem of efficiently and accurately producing anti-reflective coatings in various substrates. This research spans disciplines and involves lasers, custom tools, high frequency simulation, software development, and careful metrology.

In addition to the work being done for the SPT-3G third generation camera, the ObsCos lab is working on the larger problem of efficiently and accurately producing anti-reflective coatings in various substrates. This research spans disciplines and involves lasers, custom tools, high frequency simulation, software development, and careful metrology.

Research Activities: SQUID Readout Boards for SPT-3G

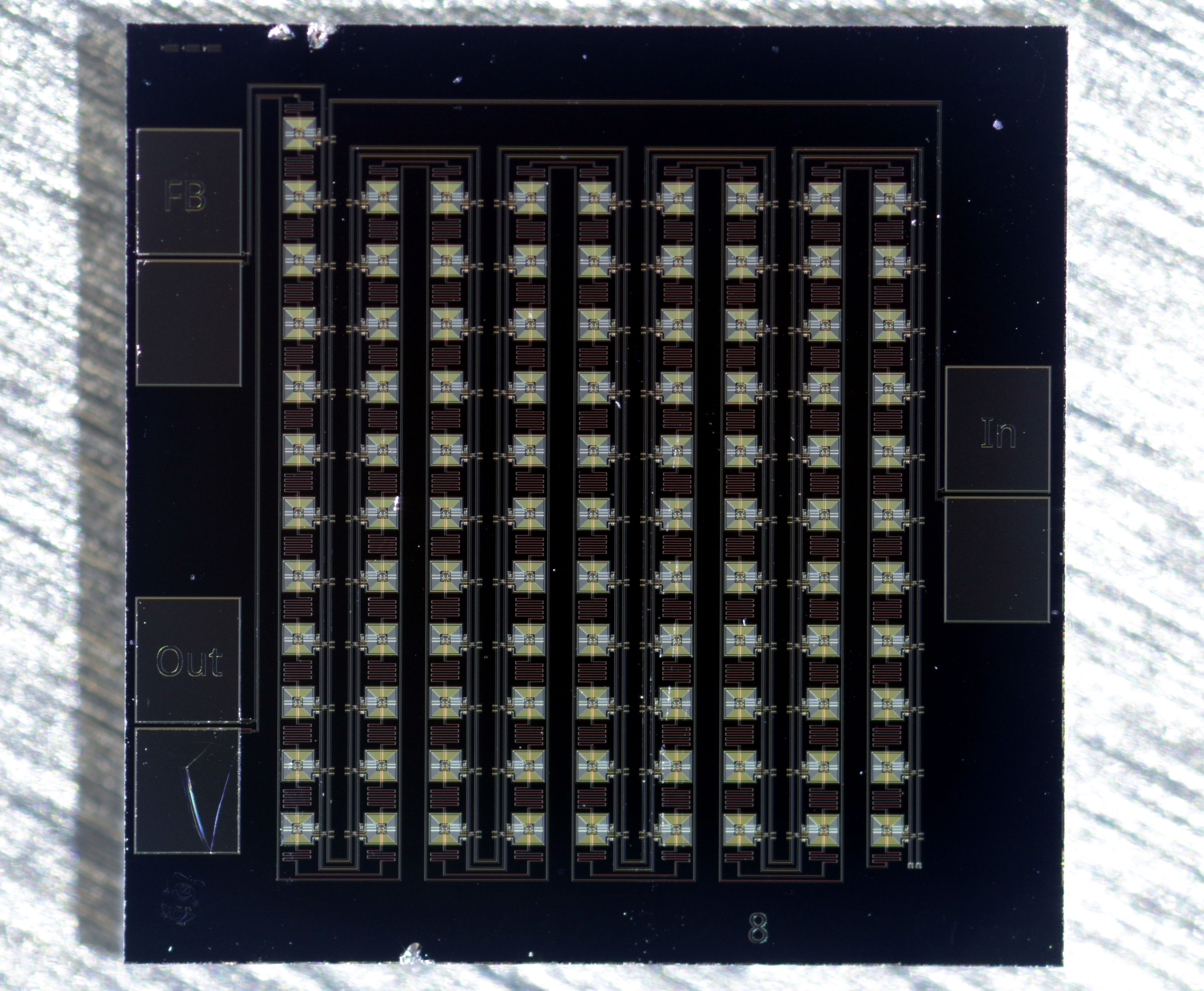

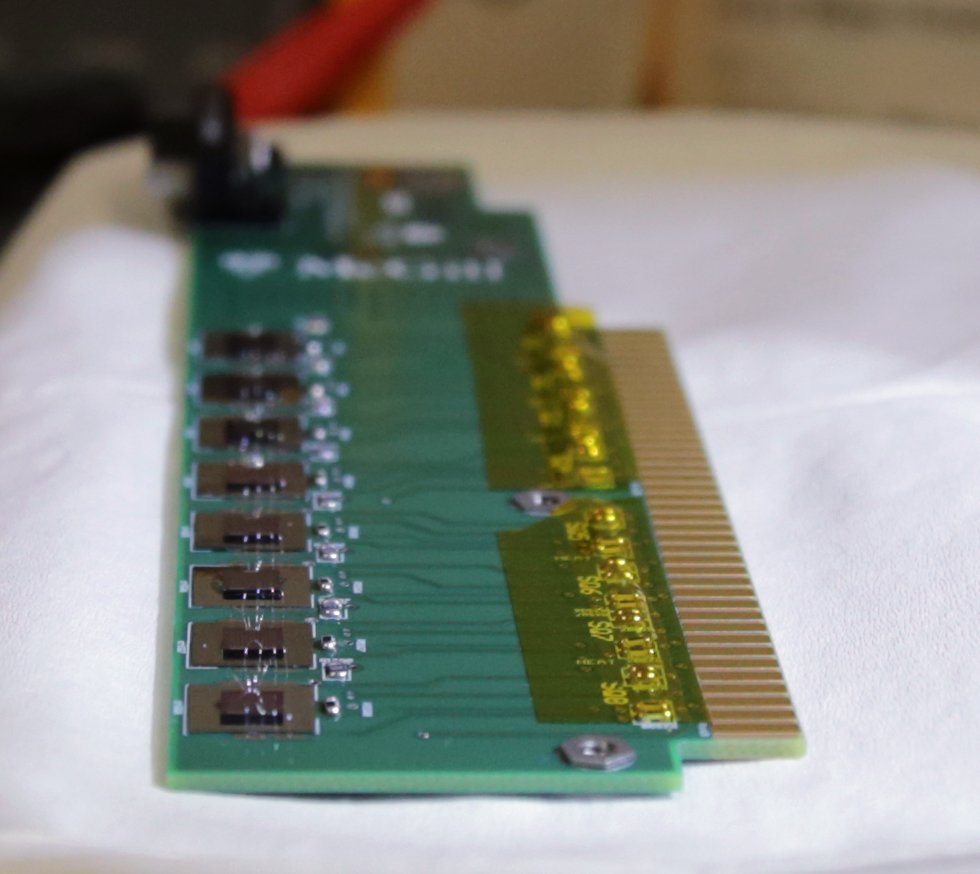

SQUID array

SPT-3G will have over 15,000 bolometers, a factor of 10 increase over its predecessor, SPT-POL. To read out such a large number of detectors, Superconducting Quantum Interference Devices, or SQUIDs, are used to read out multiple bolometers per SQUID. This technique is known as “multiplexing”. SQUIDs themselves consist of at least two Josephson junctions (where an electrical insulator is sandwiched between two superconductors), arranged in a loop, which allows them to measure extremely small magnetic fields.

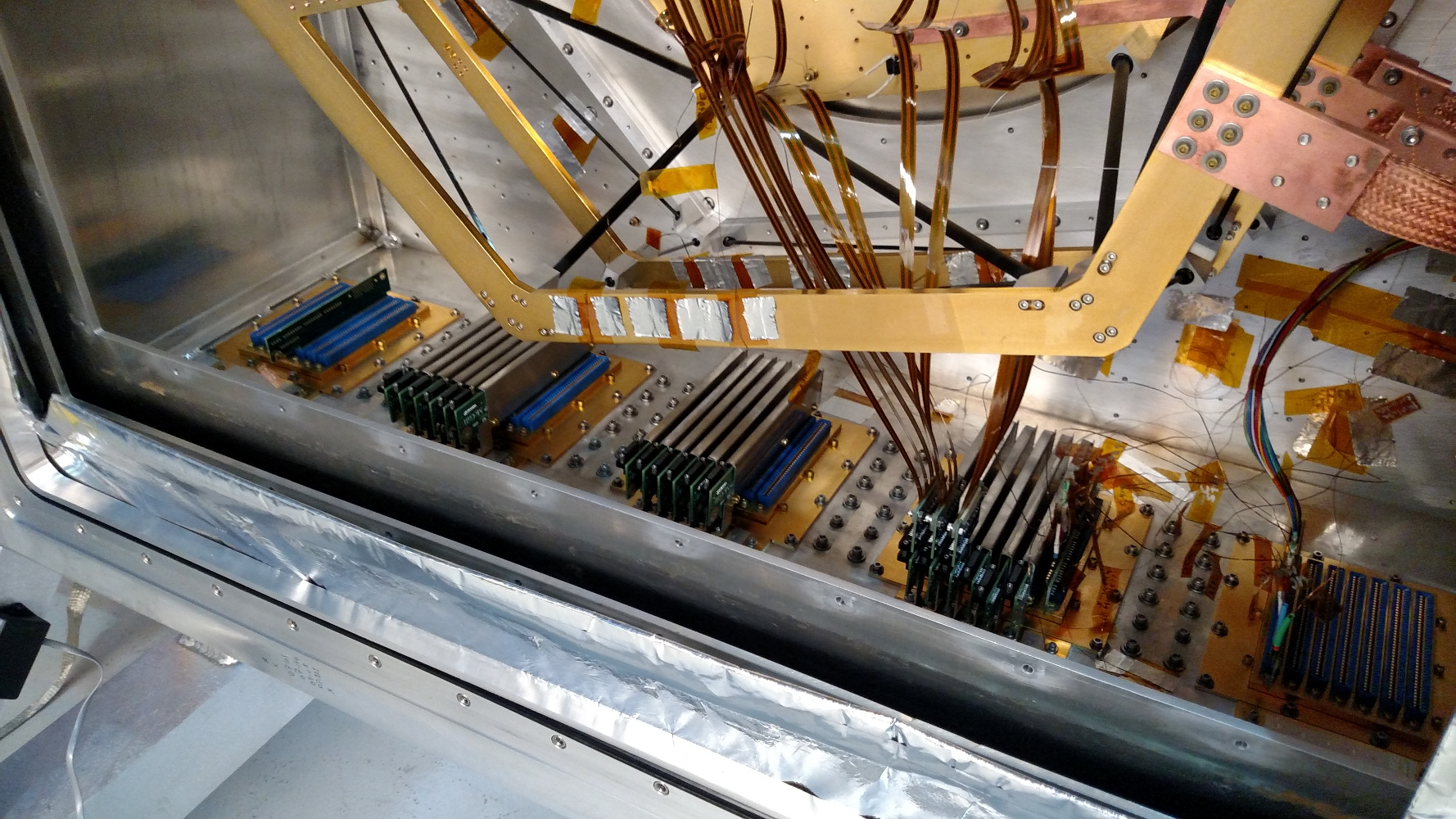

Professor Vieira’s group is involved in producing printed circuit boards for SPT-3G, each containing 8 100-element SQUID arrays, as pictured. His group is responsible for attaching connectors and surface-mount components, affixing Niobium magnetic shielding, mounting and wire-bonding the SQUIDs themselves, and circuit testing for both the boards and the SQUIDs. Completed boards are then sent to Fermilab for integration into the receiver system (pictured below), and for testing the SQUIDs’ superconducting properties at 4 Kelvin.